Autoclaving. Containers are put in an autoclave and subjected to substantial-pressure steam to destroy microbes.

Make sure that the scales within the filling device are calibrated by means of IPC station, and these types of activity shall be carried out less than creation affliction

They're going to also require info that should help them approach your task. Working a pilot batch permits you to make the production program you must exhibit co-packers that the merchandise is prepared for full-scale bottling.

Leaping into comprehensive-scale manufacture of your beverage can be complicated. Many beverage model house owners these days are Benefiting from compact-scale pilot generation runs (pilot runs) to cut back their danger and test their principle before shelling out countless Countless bucks on a full-scale output.

Place supervision is available for each shift. People usually are not authorized in the region with no supervisor. Posters can be obtained stating no pictures.

These pharmaceutical-grade plastic containers exemplify a chance to quickly handle world wide overall health desires via scalable generation abilities.

This whole in-procedure checking program ought to be done According to the plan and written specified exam restrictions and standards. All outcomes ought to be reported and evaluated formally against those restrictions.

Learn more about our special approach to manufacturing and how this unlocks the configurability of Mycap®.

Due to this fact, corrective and preventive actions might be promptly executed to limit any opportunity creation losses while also making certain the consistent excellent of ultimate drug items.

Present day aseptic filling gear utilize RABS (limited obtain barrier program) or isolator technologies. Both equally RABS and Isolators restrict outdoors contamination in the filling method and manage ISO 5/Class A ailments inside the filling and packaging parts. These rooms tend to be more generally called website clean up rooms.

The written content of our Web site is always available in English and partly in other languages. Opt for your chosen language and we will tell you about the information in that language, if obtainable.

We foresee needs with transforming industry ailments to stay in time, in stock, compliant & price tag aggressive

For the risk relevant to conducting a solution filter integrity exam before beginning filling operation, the effect of not doing the filter take a look at or even the unreliable tests result's a a significant violation of GMP tips (item contamination). The full RPN is calculated to become two hundred (red). Below the team click here chose to check and examine the primary reason and found which the creation employees relies on using guide air bubble integrity checks. The outcome are noticed and recorded manually.

Fully automatic, semi-automated and handbook inspection; plunger rod insertion; automatic commercial labeling; second facts matrix verification; variable print knowledge

Devin Ratray Then & Now!

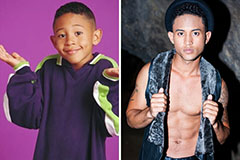

Devin Ratray Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!